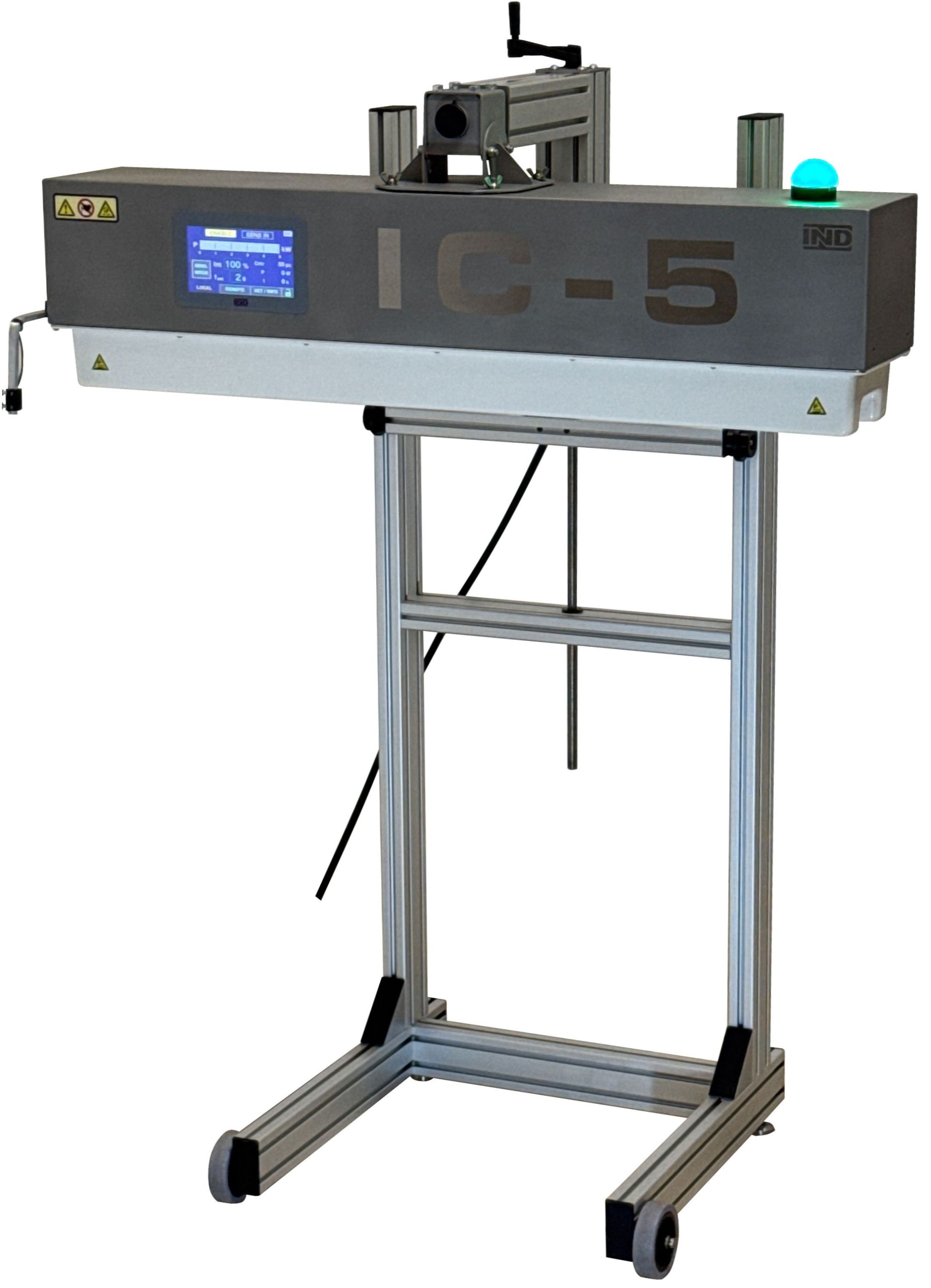

The automatic induction sealing machine will prove itself during continuous production, requiring high efficiency.

The sealing machine we offer is:

Very efficient

Our sealing machine allows containers to move very quickly under the induction head. We have achieved this by extending the head to almost 1.2 meters, thus extending at the same time the residence time of the containers under the sealing machine at the set speed of the conveyor belt. The maximum power of the sealing machine is as much as 5 kW.

The electronics of the sealer are air-cooled, so the sealer does not need an additional water-powered cooler. Such a solution saves a lot of space and allows the device to be placed almost anywhere in the production line.

Durable and reliable

The sealing machine we offer is powered by three-phase current, which, compared to the previous single-phase solution, allowed us to use even more durable and reliable components.

3 types of heads for optimal results

Induction inserts differ in design and size. Placed in the same elecromagnetic field of the welding machine, different induction inserts will heat up differently and at different rates.

Therefore, it is important to correctly select the head for the inserts and containers to be sealed.

We have 3 types of heads:

- narrow tunnel - designed for sealing containers with inserts with a diameter of 10 to 100 mm

- standard tunnel - designed for sealing containers with inserts with a diameter of 20 to 130 mm

- flat - designed for sealing containers with two-part inserts, joined with wax, with diameter over 80 mm

We have a test device at our disposal. We strongly recommend testing the sealing of containers in conditions as close to real as possible before making a purchase.

Possible integration with other devices

We have equipped our sealing machine with a communication interface, which makes it possible to control the sealing machine with signals from outside, as well as to receive signals from the sealing machine to control other devices.

Example use of the communication function:

- Making the possibility of switching on the packaging line dependent on receiving a ready signal from the induction sealer

- Stopping the packaging line when a sealer malfunction occurs

- Immediately stopping the operation of the sealing machine when an external signal is received, indicating, for example, a blockage on the production belt.

Easy to operate

An important advantage of the device we offer is its intuitive operation. The sealing machine is equipped with a touch screen, thanks to which setting the parameters of its operation is uncomplicated and fast. Placing the device over the conveyor belt, adjusting the height at which the head is located and possibly changing the position of the optical sensor, detecting the next containers, are very easy.

We provide fast warranty and post-warranty service

We have been supplying induction sealing machines to the Polish market for more than 20 years. Our automatic sealing machines are manufactured in Europe, in the same place for years, with the commitment of the third generation of its creators.

We guarantee a very fast response to service requests. We service all the devices we put on the market, regardless of their age.

Do you want to seal a container? Contact us.